The gasket keyboard is a type of mechanical keyboard that incorporates a gasket to absorb the impact of keystrokes. Usually made of rubber or foam, the gasket is positioned between the keyboard’s plate and its case. By doing so, this design effectively diminishes noise and vibration, resulting in a typing experience that is both gentler and more pleasant.

Gasket keyboards are used to enhance the overall feel and sound of typing. They are essential because they offer a quieter, more satisfying typing experience by dampening the noise when pressing keys. This also helps to prevent fatigue during extended typing sessions, making them ideal for professionals who type a lot.

The practice of gasket mounting in keyboards was initially developed to enhance typing comfort and improve sound quality. As time passed, keyboard enthusiasts and manufacturers conducted various trials using different materials and designs to optimize this mounting technique. Gasket keyboards have gained popularity among mechanical keyboard enthusiasts who highly appreciate a superior and polished typing experience.

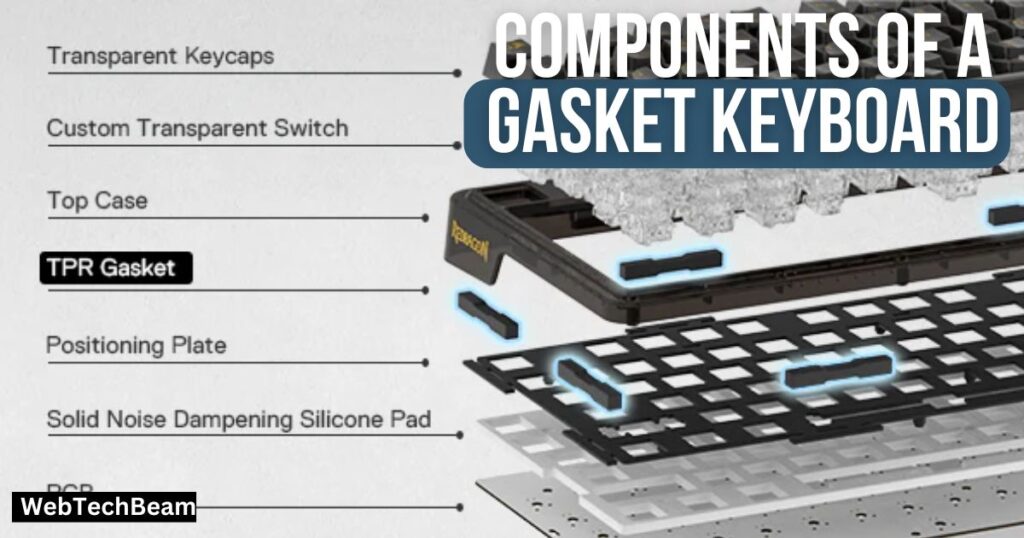

Components of a Gasket Keyboard

Gasket Mount

The gasket mount plays a vital role in a gasket keyboard, usually comprising a gasket material such as rubber or foam placed between the keyboard’s plate and case. Its purpose is to provide a cushioning effect on keystrokes, effectively minimizing noise and reducing the impact experienced while typing.

Types of Gasket Materials:

- Rubber: Provides a soft feel and good durability.

- Foam: Offers excellent cushioning and sound dampening.

Benefits of Using a Gasket Mount:

- Noise Reduction: The gasket material absorbs the sound of critical presses, making the keyboard quieter.

- Enhanced Typing Comfort: It reduces the vibrations transferred to your fingers, providing a more comfortable typing experience.

- Improved Durability: The cushioning material can help prevent damage to other keyboard components over time.

Keyboard Frame

The keyboard frame plays a crucial role in maintaining the stability and safeguarding the internal components by serving as the outer structure that holds them all together.

Construction and Materials Used in the Frame:

- Aluminium: Known for its strength and durability, aluminium frames offer a premium feel.

- Plastic: A more affordable option, plastic frames can still be durable and lightweight.

- Wood: Sometimes used for a unique aesthetic, wood frames can offer a distinct look and feel.

PCBs and Switches

How the keyboard functions depends on the essential components, namely the Printed Circuit Board (PCB) and switches.

Compatibility and Types of PCBs and Switches Used in Gasket Keyboards:

- PCBs: Most gasket keyboards use a custom PCB designed to fit the specific layout and design of the keyboard. These PCBs are compatible with various programmable features and layouts.

- Switches: Gasket keyboards can use different mechanical switches, such as Cherry MX, Gateron, or Kailh. The choice of switches can affect the keyboard’s typing feel, sound, and overall performance.

What is a Gasket Mounted Keyboard?

A gasket-mounted keyboard is a type of mechanical keyboard that incorporates special materials such as rubber or foam between its internal components. These materials, referred to as gaskets, contribute to a smoother and quieter typing experience.

By providing a cushion for each key press and minimizing noise, the gaskets enhance typing comfort during long sessions.

This design also protects the keyboard’s inside parts from wear and tear. People who love mechanical keyboards often prefer gasket-mounted keyboards because they offer a premium typing experience.

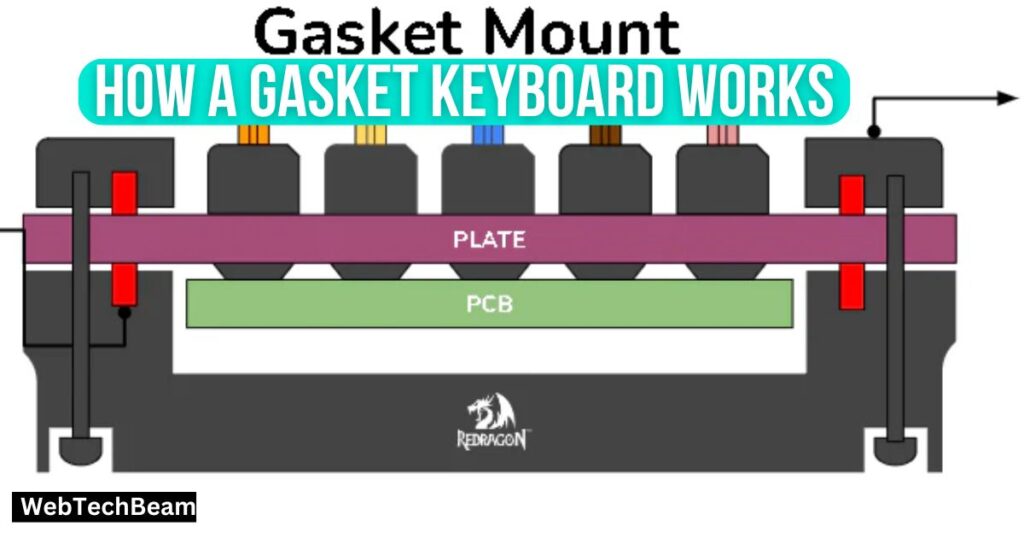

How a Gasket Keyboard Works

Mechanism

The purpose of a gasket keyboard is to offer a distinct and cozy typing encounter. Here’s the functioning mechanism behind it:

Pressure Distribution

By utilizing gasket material, the pressure generated by your keystrokes is effectively distributed in a uniform manner. Whenever a key is pressed, the gasket undergoes slight compression, effectively diffusing the force and averting any severe collisions between the keyboard’s plate and case.

Shock Absorption

The gasket functions as a shock absorber, providing a cushioning effect upon pressing the keys. By doing so, it minimizes the strain on your fingers and hands, resulting in a more comfortable and less fatiguing experience while typing for extended periods of time.

Vibration Damping

When typing, vibrations can travel from the keys to the frame of the keyboard. However, the gasket material helps to reduce these vibrations, resulting in less noise and a more peaceful typing experience.

Assembly Process

To put together a gasket keyboard, a series of steps must be followed. Presented below is a detailed, step-by-step guide to assist you in comprehending the procedure:

Step 1: Prepare Components

Gather all the necessary parts, including the keyboard frame, PCB, switches, gasket material, and keycaps. Ensure you have all the tools required for assembly, such as a screwdriver and tweezers.

Step 2: Install the Switches

To start, place the mechanical switches onto the PCB. Ensure that each switch is firmly fixed in position. If you have a hot-swappable PCB, you can effortlessly plug in the switches without the need for soldering.

Step 3: Attach the Gasket

To effectively cushion the keystrokes, evenly distribute and securely attach the gasket material around the edges of the keyboard plate.

Step 4: Mount the PCB and Plate

Make sure to align the PCB, keyboard plate, and gasket accurately. Fasten them together while ensuring that the gasket is placed between the keyboard plate and the case to maintain its position.

Step 5: Insert the PCB and Plate into the Frame

Make sure to fit the assembled PCB and plate with the gasket securely into the keyboard frame, ensuring a tight fit and checking for any loose parts.

Step 6: Screw the Frame Together

To ensure a stable structure, utilize a screwdriver to fasten the frame securely, ensuring all screws are tightened.

Step 7: Add Keycaps

Afterward, securely affix the keycaps onto the switches. Apply firm pressure to ensure proper seating of each keycap.

Step 8: Test the Keyboard

After assembling, establish a connection between the keyboard and a computer to verify the proper functioning of each key. In case certain keys are not operating correctly, carry out any required adjustments.

By following these steps, you will be able to assemble a gasket keyboard and indulge in its distinctive typing experience.

Advantages of Gasket Keyboards

Typing Comfort: Enhanced Comfort Due to Cushioning Effect

Typing becomes significantly more comfortable with the presence of the gasket material in the keyboard. By absorbing the pressure exerted when a key is pressed, the gasket acts as a cushion, safeguarding your fingers against harsh impacts. This pleasant sensation alleviates hand strain, enabling you to type effortlessly for extended periods without experiencing any discomfort.

Sound Damping: How Gasket Mounts Contribute to Quieter Typing

Gasket mounts are beneficial in reducing typing noise by absorbing the sound produced when keys are pressed. They effectively prevent the transmission of noise from the keyboard to the desk, resulting in a significantly quieter typing experience. This feature is particularly advantageous in quiet environments or shared workspaces where minimal noise disturbance is desired.

Stability and Flexibility: Improved Stability and Flexibility Provided by the Gasket

The gasket material adds both stability and flexibility to the keyboard. It helps keep all the parts tightly in place, reducing unwanted movement. At the same time, it allows flexibility, so each key press feels smooth and consistent. This balance enhances the overall feel and performance of the keyboard, making it a joy to use.

Disadvantages of Gasket Keyboards

Cost

Gasket keyboards come with a significant drawback, primarily due to their higher price. Compared to traditional keyboards, they tend to be more costly as they incorporate specialized materials and boast a distinctive design.

Complexity

Additionally, beginners may find it challenging to assemble these keyboards due to the intricate process involving multiple steps and the need for precise fitting to ensure everything is in place.

Durability Concerns

As time passes, the gasket material in these keyboards may deteriorate, leading to a decrease in its effectiveness in cushioning keystrokes and reducing sound. This deterioration can potentially impact both the performance and comfort of the keyboard.

What is the difference between a tray and a gasket keyboard?

| Feature | Tray Keyboard | Gasket Keyboard |

| Mounting Method | Key switches are mounted directly to a tray | Key switches are mounted on a gasket |

| Sound Profile | Typically louder, more pronounced | Quieter, dampened sound |

| Typing Feel | Firmer, more rigid typing experience | Softer, more cushioned typing experience |

| Vibration Dampening | Less vibration absorption | Better vibration dampening |

| Assembly Complexity | Generally simpler to assemble | More complex to assemble |

| Key Switch Flexibility | Less flexibility in key switch movement | More flexibility, key switches can flex |

| Cost | Usually more affordable | Often more expensive |

| Customizability | Limited customizability | Higher level of customizability |

| Popularity | Common in budget and mid-range keyboards | Common in high-end and custom keyboards |

| Durability | Generally durable | Can be less durable due to gasket wear |

Conclusion

The gasket keyboard utilizes special materials to offer a one-of-a-kind and pleasant typing experience. With the inclusion of gasket mounts, this keyboard provides cushioning that absorbs pressure, minimizes strain, and dampens sound. As a result, it is notably quieter and more stable compared to conventional keyboards.

Gasket keyboards are known for their exceptional comfort, noiseless performance, and superior stability. Although they may involve higher costs and additional complexity during assembly, their advantages make them a fantastic option for individuals seeking to enhance their typing experience.

What is a Gasket Keyboard? – Web Tech Beam Best info in 2024